What best describes the items you are interested in storing, retrieving, transporting or sorting?

Garments, |

Products, |

Greenhouse & |

I have an |

Garments, |

Products, |

Greenhouse & |

I have an |

Distribution Centers & |

Retail Stock Rooms |

|

Parts Storage |

Factory, Processing & |

Existing System Rehab or Refurbishment |

Existing system software upgrade |

White Conveyors Comp-U-Sort™ is the leading edge of garment sorting technology.

Automated Comp-U-Sort Systems were designed to improve productivity by providing a more efficient means of sorting garments on hangers. Common applications include: high volume industrial laundries, institutional laundries, dry cleaners and retail organizations requiring automated sorting.

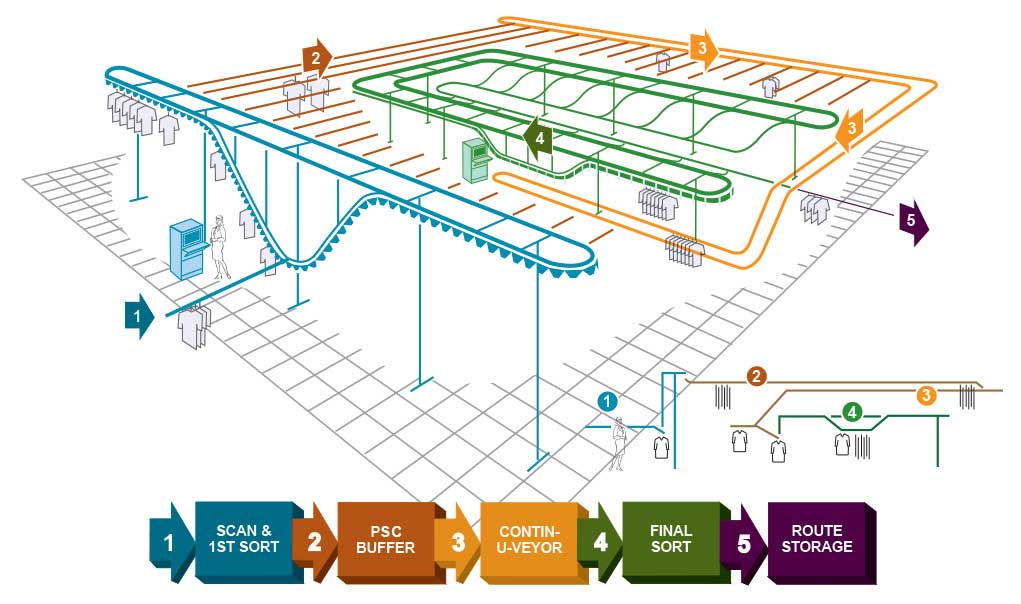

From the finishing tunnel, each garment is fed into the first sort loading station where it is automatically scanned and loaded onto a CUS-OAS for initial (batch or route) sorting. The system’s scanner can be programmed to read bar codes, or radio frequency identifiers. Once scanned, each garment’s identity and location are continuously monitored from start to finish. The system can handle the output of multiple finishing tunnels, and is capable or sorting over 7,000 pieces per hour without an operator.

Garments for each batch are automatically discharged onto an overhead PSC storage system or gravity feed rails. The PSC is superior to gravity rails because it ensures that garments aren’t crushed and open work space is available underneath. The PSCs can be installed in rooms with as little as a 14' ceiling and still provide open floor space.

On demand, the PSCs off-load their sorted garments onto a Contin-U-Veyor which takes them to a Comp-U-Sort. This final sort combines route, account, man and garment type in one non-linear process. The patented Comp-U-Sort technology, which includes a powerful and flexible database system, completes the final sort quickly with all garments in perfect order, ready for tie out and delivery to your customers.

If route storage is necessary, the garments may be moved on a Contin-U-Veyor to a route holding area, again by using overhead PSCs. Clear floor space is available for other work activities. A Contin-U-Veyor would then deliver the garments directly to your loading dock.

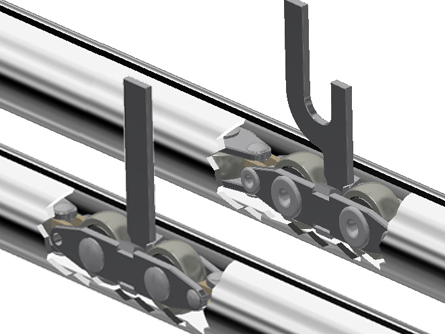

Automatically sorts over 7,000 garments per hour to any number of stations. This high capacity sorting conveyor is ideal for separating large groups of unsorted garments into batches or routes. Operators feed individual standard hangers to the moving conveyor. Our system does not require mother hooks, escorts or other auxiliary devices. The positive latching mechanism holds the hanger in place until it is discharged at the predetermined station. Multiple operators, combined with its speed, make the CUS-OAS an ideal conveyor for use in multiple tunnel applications.

Combines multiple sorts into one operation. An entire route or group can be sorted into any predetermined order, with minimal labor and maximum speed. The Comp-U-Sort computer records the garment identifier and relates it to a latch location on the conveyor. The fastest discharge order is computed, and garments are automatically routed accordingly. Upon determining your daily production, the conveyor is engineered to meet your particular requirements.

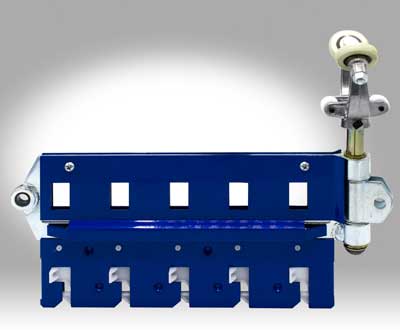

A level rail that accumulates, discharges, and moves forward or backward under your control. Standard individual hangers or bundles are discharged onto the PSC. The entire line then moves forward, separating each garment. Garments are discharged from the opposite end of the overhead PSC to a take-away conveyor. Because the PSC is elevated and parallel to the floor, you are able to utilize the full cube of your facility...virtually doubling your available space. The quality produced is the quality shipped, as there are no gravity lines to crush garments. The spacing of garments is easily controlled, either manually or by programmable logic controllers (PLCs). This flexibility allows you to change the density of each rail as needed.

A continuous power chain conveyor. The efficient and economical transport conveyor ties together everything in your plant. Whether used in a finishing tunnel, for sorting or for route storage, this versitile conveyor can go anywhere...between floors, around corners, or up and down inclines. The entire system is made up of durable modular components including drive units, track & chain, unloading devices and take-up units. Systems can be engineered to incorporate air operated take-ups and dual drives for the most demanding conditons. To further assure long-term durability, all conveyor tracks are constructed of stainless steel.

Comp-U-Sort’s latest Windows operating system and user friendly software interfaces with your existing data management system and can facilitate various production reports. Garments usually start out completely scrambled. Comp-U-Sort uses the information supplied by each garment’s unique identifier, and delivers all garments to their proper location in perfect order in an optimized sorting sequence.